The First Stage of Hatmaking

This video illustrates the traditional process of transforming beaver pelts into felt hat bodies. It shows how raw pelts are cleaned, their fibers loosened, and then matted together through felting to form a dense, durable material. The felt is gradually shaped into large cone-like forms known as hat bodies, which serve as the starting point for hatmakers. From there, the next stage begins: taking those hat bodies and refining them through blocking, shaping, sanding, stitching, and finishing to create the final hat.

Shaping the Felt

We start with the finest fur felts of beaver, nutria and rabbit, sourced for their density, durability, and hand-feel. Using steam and wooden hat blocks, the felt is softened, stretched, and carefully shaped. This creates the foundation, the crown and brim that defines the character of the hat.

Pouncing

Once the form is set, the surface is hand-pounced (sanded) in stages. This process refines the felt, creating a smooth, luxurious finish while keeping the body strong. It’s a slow, meticulous step that brings out the true quality of the fur felt.

Cutting & Shaping the Brim

The brim is measured, cut, and sanded to the exact proportions of the design. Using heat and steam, the brim is then flanged given its curve and snap so it holds its shape through years of wear.

Shaping the Crown

With the hat body ready, we block the crown to its final style. Whether it’s a classic cattleman crease, a pinched front, or an open crown ready for custom shaping, this stage sets the silhouette that gives each hat its unique identity.

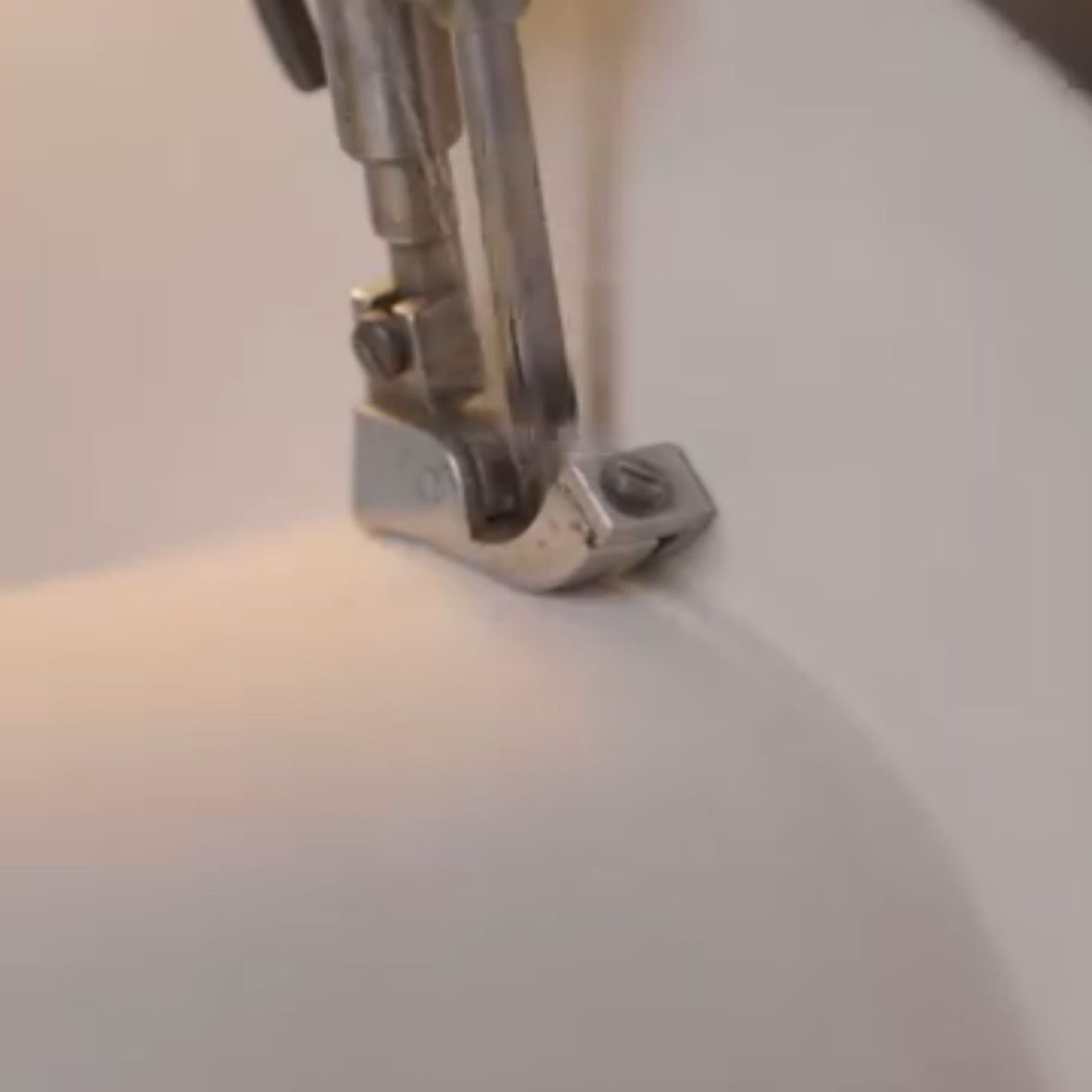

Sweatband & Liner

The inside of the hat matters just as much as the outside. A premium leather sweatband is hand-stitched into place, conforming to the head for comfort and durability. Depending on the design, we add a satin liner, stamped with the Hitmaker mark of authenticity.

Trimmings & Details

The final details make the hat. Grosgrain ribbons, leather bands, or custom beading are sewn and set by hand. Every detail is chosen to complement the hat’s character while honoring heritage craft.

Final Touches

Before leaving the shop, every hat is brushed, inspected, and shaped once more to ensure it meets our highest standards. The result: a hat that feels like it was made just for you, ready for a lifetime of hard wear and good stories.